What is Food Grade Gases?

Food grade gases refer to gases that are used in the food and beverage industry for various purposes, ensuring the safety, quality, and preservation of food products. These gases are specifically manufactured, handled, and controlled to meet strict standards and regulations to ensure they are safe for use in food-related applications.

Types of Food Grade Gases

Some common types of food grade gases include:

- Carbon Dioxide (CO2): Carbon dioxide is widely used in the food industry for carbonation, as it gives beverages like soda, beer, and sparkling water their characteristic fizz. It is also used in modified atmosphere packaging (MAP) to extend the shelf life of packaged food products by inhibiting microbial growth and preventing oxidation.

- Nitrogen (N2): Nitrogen is often used in food processing and packaging applications to create a controlled atmosphere that helps preserve the freshness and quality of food products. It is an inert gas that displaces oxygen, reducing the risk of spoilage, rancidity, and color changes caused by oxidation. Nitrogen is commonly used in MAP, particularly for products like snacks, coffee, nuts, and grains.

- Oxygen (O2): Oxygen is required for many biological processes, and controlled amounts of oxygen are used in some food processes such as fermentation. Oxygen may also be used in specific applications where the addition of oxygen enhances product characteristics, such as in the production of certain bakery products and some beverages.

- Nitrous Oxide (N2O): Nitrous oxide, commonly known as “laughing gas,” is used as a propellant in aerosol whipped cream dispensers. It helps create a whipped texture and provides stability to the whipped cream.

- Helium (He): Helium is sometimes used in the food industry for its inert properties. It can be used for pressurizing and leak testing food containers and packaging, ensuring their integrity and safety.

Visit us to learn more about food grade gases market

https://www.databridgemarketresearch.com/reports/global-food-grade-gases-market

Ensuring Product Consistency with Food Grade Gases in the Dairy Industry

In the dairy industry, ensuring product consistency is of utmost importance to meet consumer expectations and maintain brand reputation. Food grade gases play a vital role in achieving this consistency by offering various benefits throughout the dairy production process. Here are some ways in which food grade gases help ensure product consistency in the dairy industry:

- Pasteurization: Pasteurization is a crucial step in dairy processing that involves heating milk or milk products to eliminate harmful bacteria while preserving its nutritional value. Food grade gases, particularly steam, are used in the pasteurization process to heat the milk quickly and uniformly, ensuring the destruction of pathogens and extending shelf life.

- Packaging: Food grade gases, such as nitrogen and carbon dioxide, are used in packaging processes to maintain product freshness and quality. Modified atmosphere packaging (MAP) involves replacing the air inside the packaging with a specific gas mixture to create a controlled atmosphere. Nitrogen is commonly used to displace oxygen, reducing the risk of spoilage, microbial growth, and oxidation. This helps extend the shelf life of dairy products and maintain their taste, texture, and appearance.

- Dairy Product Whipping: Whipped dairy products, such as whipped cream, require the use of food grade gases like nitrous oxide. Nitrous oxide acts as a propellant in aerosol dispensers, creating a whipped texture and stability in the final product. The precise control and consistency provided by nitrous oxide ensure uniform and desirable results across batches.

- Carbonation: Carbonated dairy beverages, like carbonated milk-based drinks, rely on carbon dioxide for the characteristic fizz and refreshing taste. Carbon dioxide is used to carbonate the beverage, creating bubbles and enhancing the sensory experience for consumers. Consistent carbonation levels are essential to maintain product quality and consumer satisfaction.

- Freezing and Cold Storage: Food grade gases, particularly liquid nitrogen, are used in the dairy industry for rapid freezing and cryogenic cold storage. Rapid freezing helps preserve the texture and nutritional quality of dairy products by minimizing ice crystal formation. Cryogenic cold storage using liquid nitrogen helps maintain the quality and integrity of frozen dairy products during transportation and storage, reducing the risk of freezer burn and maintaining product consistency.

Growth in food grade gases market

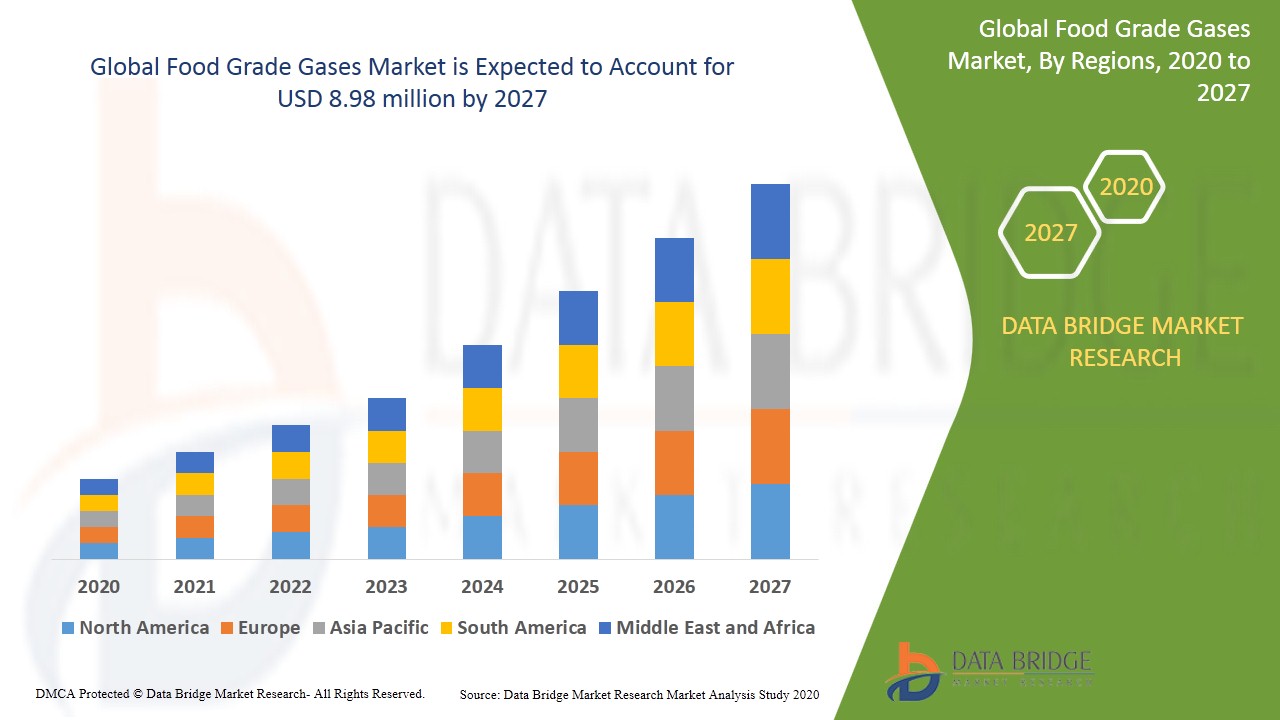

- The food grade gases market is anticipated to reach USD 8.98 billion by 2027, expanding at a growth rate of 3.27% from 2020 to 2027. It is anticipated that rising demand for frozen food items would open up new business opportunities.

- The food industry’s rising demand is anticipated to boost market expansion. During the forecast period of 2020 to 2027, the market for food grade gases is anticipated to be driven by a number of other factors, including a rise in the use of smart packaging to extend shelf life, need for fast freezing of fresh foods, technological advancements, and an increase in meat and seafood trade.

Why choose us

An organisation that prides itself on providing thorough and reliable analyses of various markets and customers throughout the world is Data Bridge Market Research. The distinctive goal of Data Bridge Market Research is to offer clients the highest quality, most detailed research possible. Our market research studies for global, regional, and country level market segments, broken down by goods, services, technologies, applications, end users, and market players, allow our customers to see more, know more, and do more, which helps them find the answers to their most pressing problems.