Heating chambers, also known as industrial ovens or thermal chambers, play a crucial role in the manufacturing industry. These chambers provide controlled heating environments essential for various manufacturing processes, including curing, drying, annealing, and heat treatment. This article explores the significance of heating chambers in the manufacturing industry, detailing their applications, benefits, technological advancements, and future trends.

In the automotive and aerospace industries, heating chambers are extensively used for curing paints and coatings. The curing process involves applying heat to accelerate the drying and hardening of paint, ensuring a durable and high-quality finish. This process is critical for achieving the desired aesthetic and protective properties of the coatings.

Composite materials, widely used in aerospace and automotive sectors, require curing to achieve optimal strength and stability. Heating chambers provide the precise temperature control necessary for curing composite materials, ensuring uniformity and integrity in the final product.

Annealing is a heat treatment process used to soften metals, improve their ductility, and relieve internal stresses. Heating chambers provide the controlled environment needed for annealing, allowing manufacturers to achieve desired material properties such as increased malleability and reduced brittleness.

Tempering is another heat treatment process used to improve the toughness of hardened steel and other alloys. By carefully controlling the temperature and duration of the tempering process, heating chambers help manufacturers achieve the required balance between hardness and toughness in metal components.

In industries such as electronics and pharmaceuticals, removing moisture from components and materials is crucial. Heating chambers provide a controlled environment for drying, ensuring that moisture is effectively eliminated without damaging the product.

In the food industry, heating chambers are used for drying processes such as dehydration of fruits and vegetables. These chambers ensure that moisture is removed uniformly, preserving the nutritional value and extending the shelf life of food products.

Sintering involves heating powdered materials to form solid structures. This process is widely used in the manufacturing of ceramics and metal parts. Heating chambers provide the necessary temperature control to ensure uniform sintering, resulting in high-density and high-strength materials.

Heating chambers are equipped with advanced temperature control systems that allow for precise regulation of heating processes. This accuracy is crucial for maintaining the quality and consistency of manufactured products, ensuring that each batch meets the required specifications.

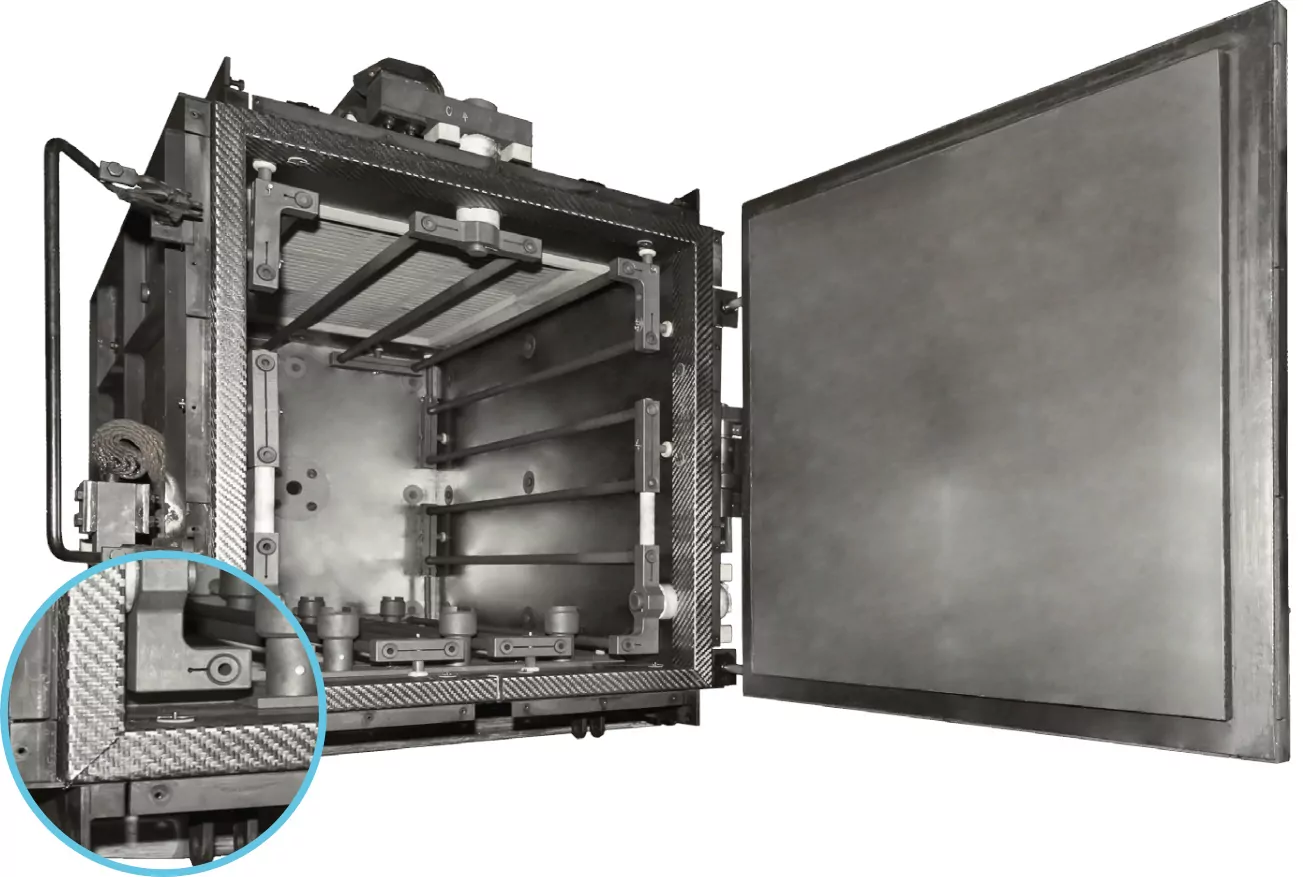

The design of heating chambers ensures even heat distribution throughout the chamber. This uniformity prevents hot and cold spots, which can lead to inconsistent results and defects in the final product. By providing a consistent thermal environment, heating chambers help maintain high standards of quality.

Heating chambers can significantly reduce processing times for various manufacturing processes. By providing a controlled and consistent heating environment, these chambers accelerate curing, drying, and heat treatment processes, leading to increased productivity and shorter lead times.

Modern heating chambers are designed with energy efficiency in mind. They use advanced insulation materials and energy-efficient heating elements to minimize heat loss and reduce energy consumption. This not only lowers operational costs but also supports sustainability initiatives by reducing the environmental impact of manufacturing processes.

Heat treatment processes such as annealing and tempering enhance the mechanical properties of materials, making them stronger and more durable. Heating chambers provide the controlled environment necessary for these processes, ensuring that materials achieve the desired properties.

In processes such as curing paints and coatings, heating chambers help achieve a superior surface finish. The controlled heating environment ensures that coatings cure evenly and adhere properly, resulting in a smooth and durable finish.

Heating chambers are equipped with safety features such as over-temperature protection, emergency shut-off switches, and alarms. These features ensure safe operation and help prevent accidents, protecting both personnel and equipment.

In industries with stringent regulatory requirements, such as pharmaceuticals and food processing, heating chambers ensure compliance with industry standards. The controlled environment provided by these chambers helps manufacturers meet quality and safety regulations, reducing the risk of recalls and legal issues.

Modern heating chambers are equipped with programmable logic controllers (PLCs) that allow for precise control of temperature, timing, and other process parameters. PLCs enable manufacturers to automate and optimize heating processes, ensuring consistent and repeatable results.

Human-machine interfaces (HMIs) provide an intuitive and user-friendly interface for controlling heating chambers. HMIs allow operators to monitor and adjust process parameters in real-time, improving control and reducing the risk of errors.

The integration of Internet of Things (IoT) technology in heating chambers enables remote monitoring and control. Manufacturers can access real-time data on chamber performance, temperature, and process parameters from anywhere, allowing for proactive maintenance and troubleshooting.

IoT-enabled heating chambers can predict maintenance needs based on real-time data and usage patterns. Predictive maintenance helps reduce downtime, extend equipment lifespan, and prevent unexpected failures, improving overall efficiency and productivity.

The use of advanced insulation materials in heating chambers reduces heat loss and improves energy efficiency. These materials help maintain a consistent temperature within the chamber, reducing the energy required to achieve and maintain the desired thermal conditions.

Modern heating chambers use energy-efficient heating elements that provide rapid and uniform heating. These elements consume less energy while delivering consistent performance, contributing to lower operational costs and a reduced environmental footprint.

As the manufacturing industry continues to embrace Industry 4.0, heating chambers are becoming more integrated with automated and interconnected systems. The integration of heating chambers with other automated processes and systems enhances overall efficiency and productivity, supporting the growth of smart manufacturing.

The use of robotics and artificial intelligence (AI) in conjunction with heating chambers is on the rise. Robots can handle the loading and unloading of materials, while AI algorithms optimize heating processes based on real-time data and predictive analytics. This combination improves accuracy, reduces labor costs, and enhances overall efficiency.

There is a growing emphasis on sustainability in manufacturing, leading to the development of eco-friendly heating solutions. Manufacturers are exploring alternative heating methods, such as infrared and microwave heating, which offer energy savings and reduced environmental impact.

The integration of renewable energy sources, such as solar and wind power, with heating chambers is becoming more prevalent. By harnessing renewable energy, manufacturers can reduce their reliance on fossil fuels and lower their carbon footprint, contributing to more sustainable manufacturing practices.

Manufacturers are increasingly seeking customized heating chamber solutions to meet their specific needs. Customization options include chamber size, temperature range, heating method, and control systems. Tailored solutions ensure optimal performance and efficiency for unique manufacturing processes.

Modular heating chambers offer flexibility and scalability, allowing manufacturers to adapt and expand their heating capabilities as needed. Modular designs enable the addition or removal of components to suit changing production requirements, providing a cost-effective and adaptable solution.

Heating chambers are indispensable tools in the manufacturing industry, providing controlled heating environments essential for various processes. Their applications range from curing and drying to heat treatment and sintering, making them vital for achieving high-quality and consistent results.

The benefits of heating chambers, including precision and control, efficiency and productivity, enhanced material properties, and safety and compliance, underscore their importance in modern manufacturing. Technological advancements, such as advanced control systems, IoT integration, and energy-efficient innovations, continue to enhance the capabilities and efficiency of heating chambers.

Looking to the future, trends such as increased automation, sustainable manufacturing practices, and customization and modularity will shape the evolution of heating chambers in the manufacturing industry. As technology continues to advance, heating chambers will play an increasingly critical role in supporting efficient, high-quality, and sustainable manufacturing processes.

This article is posted on Qasautos,

WhatsApp us