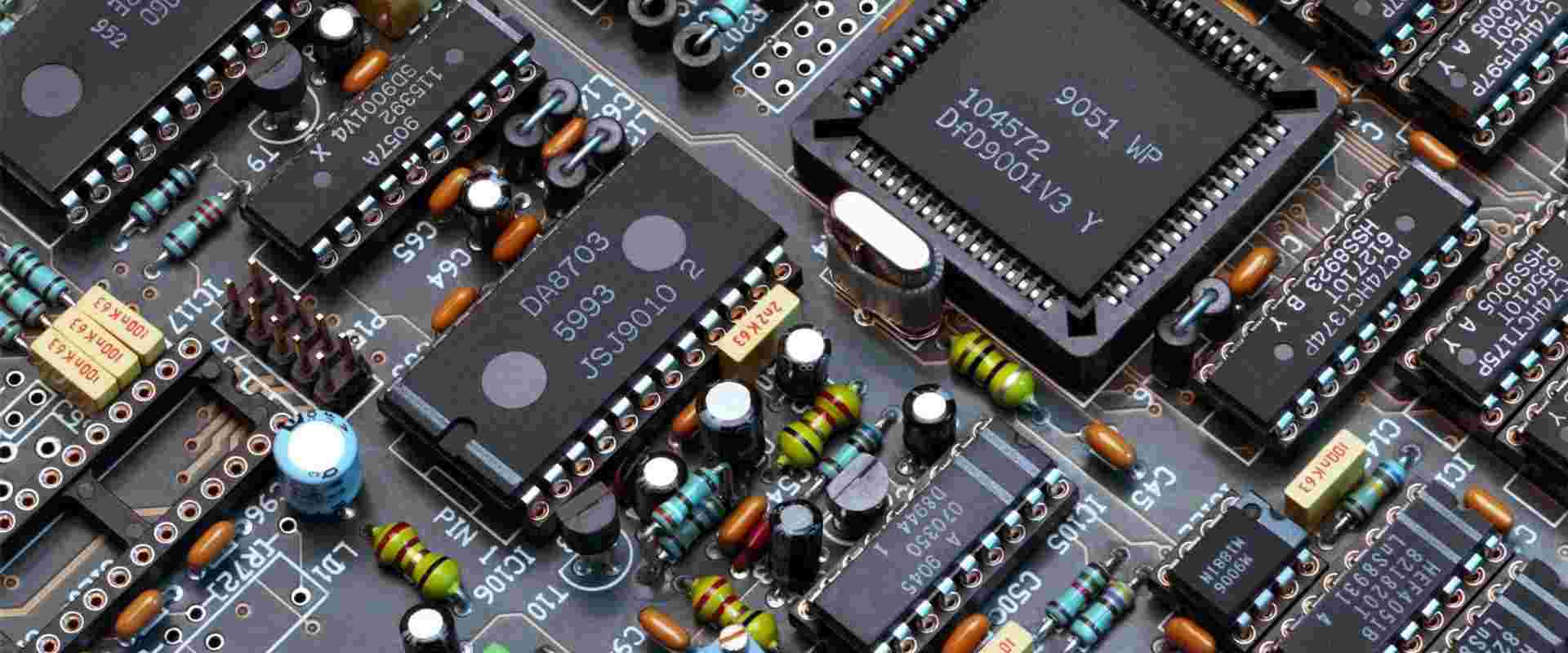

In today’s rapidly advancing technological landscape, the demand for smaller, faster, and more powerful electronic devices continues to grow. As a result, the need for efficient and reliable FS (Flex-rigid with Stacked Vias) PCBA circuit boards has become paramount.

These circuit boards offer numerous advantages, including reduced size, improved signal integrity, enhanced thermal management, and increased reliability. In this blog post, we will explore the key considerations and tips for designing an efficient and reliable FS PCBA circuit board.

Before embarking on the design process, it is crucial to clearly define the project scope and objectives. This includes gathering information about the intended application, desired performance, and any specific requirements or constraints. Consider factors such as size limitations, power consumption, signal integrity, thermal management, and any environmental considerations. Understanding these requirements will serve as a foundation for making informed design decisions.

Choosing the right components is vital in designing an efficient and reliable FS PCBA circuit board. Opt for components that are compatible with FS PCBA technology, as not all components are suitable for this type of board. Additionally, prioritize reliable and high-quality components from reputable manufacturers. Consider factors such as component availability, cost-effectiveness, environmental conditions, and lifecycle considerations. By selecting the right components, you can ensure the longevity and performance of your circuit board.

The layout of the PCB plays a significant role in its efficiency and reliability. To maximize efficiency, plan an optimized layout that minimizes signal interference and reduces noise coupling. Follow best practices for trace routing, such as avoiding sharp bends and crossing traces at right angles, as these can lead to signal degradation. Pay attention to ground plane placement to minimize noise coupling and ensure proper spacing between components to avoid thermal issues. Furthermore, consider the use of multilayer PCBs to accommodate the complex interconnections of FS PCBA technology.

Efficient thermal management is essential to prevent overheating and ensure the reliability of the circuit board. Identify potential heat sources on the PCB and plan for effective heat dissipation mechanisms. This can include using thermally conductive materials in critical areas or adding heat sinks if necessary. Additionally, properly design ventilation channels or utilize fans to maintain optimal operating temperatures. By addressing thermal management early in the design process, you can avoid potential performance issues and ensure the longevity of your circuit board.

Recommended: Find out the best laboratory equipment service and repair new york.

Signal integrity is crucial for maintaining the performance and reliability of the circuit board. To mitigate noise interference, carefully separate sensitive analog and digital signals from noisy ones. Utilize proper decoupling techniques to minimize power supply noise, such as placing decoupling capacitors strategically. If required, perform signal integrity analysis using simulation tools to identify potential issues and optimize the design. By prioritizing signal integrity, you can ensure the accurate transmission of data and minimize the risk of errors or malfunctions.

Implementing a comprehensive testing strategy is vital to ensure the functionality and reliability of the designed circuit board. As a PCB Manufacturer, you can conduct thorough functional tests before proceeding with manufacturing to identify any design flaws or performance issues. Additionally, perform validation tests under various real-world operating conditions to ensure the circuit board can withstand the intended application’s demands. Regularly review and iterate on the design based on the test results to optimize performance and reliability.

Designing an efficient and reliable FS PCBA circuit board requires careful planning, component selection, PCB layout considerations, thermal management, signal integrity optimization, and thorough testing. By following the tips outlined in this blog post, you can enhance the performance and reliability of your circuit board. Remember, understanding the requirements, selecting the right components, optimizing the PCB layout, managing thermal issues, prioritizing signal integrity, and conducting thorough testing are all key steps in achieving a successful design. By incorporating these guidelines into your design process, you can meet the demands of modern electronic devices and ensure the longevity and reliability of your FS PCBA circuit board.

WhatsApp us